5G is the fifth generation (fastest, most robust technology) network that will provide higher speed, lower latency, and greater capacity compared to 4G LTE networks. Industry 4.0, or the fourth industrial revolution is the integration of smart digital technology and emphasizes automation, machine learning, and real-time data.

Industries 4.0 need highly reliable, low latency, and secure wireless connectivity with high bandwidth to meet the requirements of AI, machine learning, and automation and here, it needs 5G – an industrial-grade private wireless network that has proven records to meet the demands of Industry 4.0 as well as business-critical applications. 5G coverage is also known to provide secure and reliable connectivity to those starting from people and machines to sensors and analytics, and 5G is meant for everything, that is, critical to your operations in industry 4.0.

Private wireless based on 5G can support almost all industrial use cases (support 85 percent of industrial use cases) and benefits a large ecosystem of industrial devices, sensors, and compatible systems. 5G private wireless network gives a competitive advantage to industry 4.0, which means you can start to upgrade your industry 4.0 by adding a 5G industrial ecosystem.

5G benefits for manufacturing:

Whether it’s wired or wireless technologies (Wi-Fi and cellular), both are used by manufacturers, and at the same time, reliability and scalability are important concerns for them. So, to meet such concerns, 5G technology has stepped forward, and it is playing a crucial role across the entire manufacturing value chain. In the future, 5G will even enable many smart manufacturing enterprises by delivering various advantages, and some of them include:

-

Ultra-reliability & security

-

Low latency

-

Device density & data volume

-

Accelerate design to the manufacturing process

-

Ability to handle mass personalization and customization

-

Improved productivity (by reducing failure rates)

-

Much higher quality (and potential to achieve zero defects)

-

Improved plant safety (by anticipating and reducing failures)

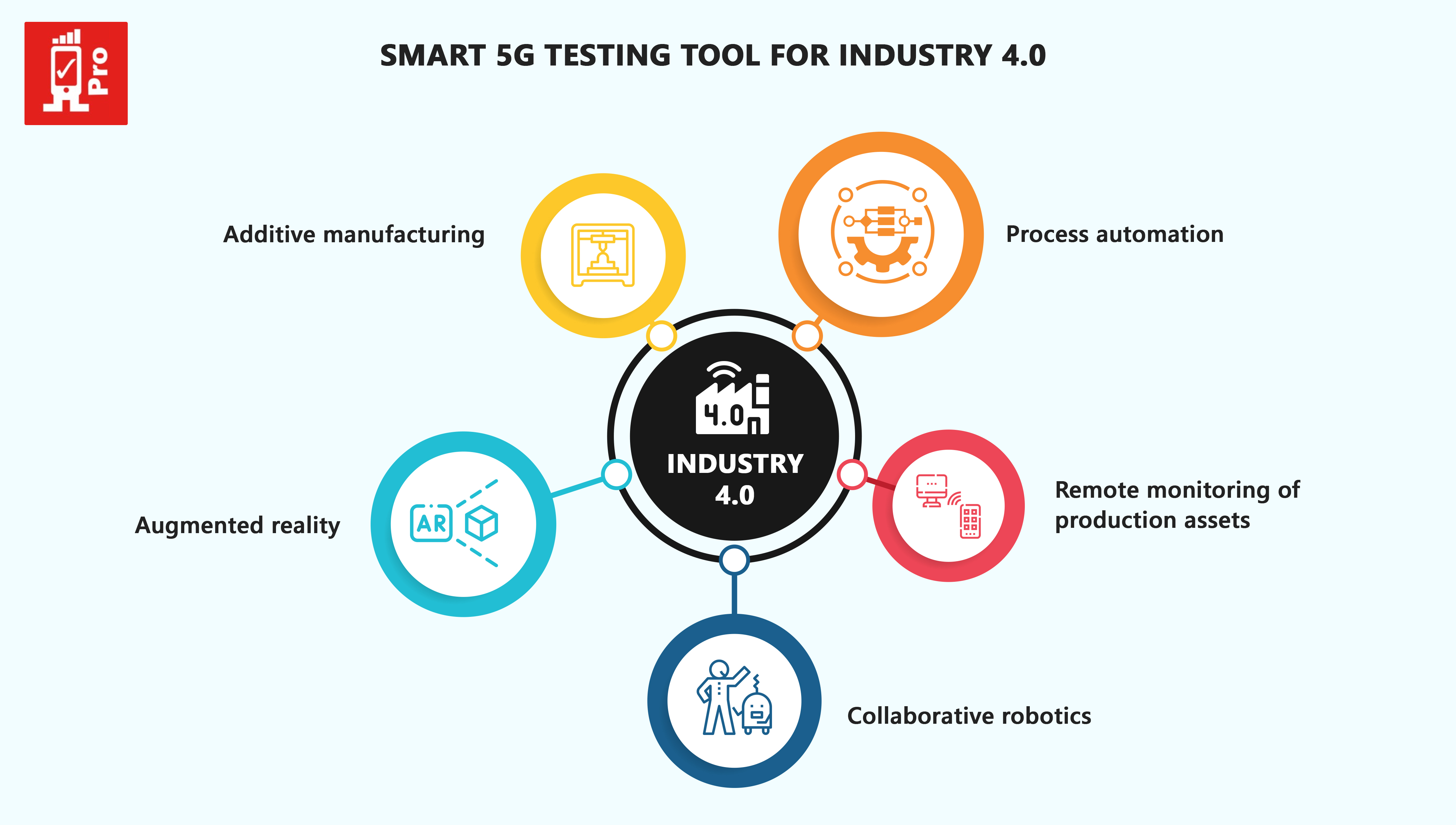

5G Use Cases in manufacturing technologies:

Process automation

Industry 4.0 and IoT (Internet of Things) have enabled to make the smart factories (ability to automate repetitive, labour-intensive, and potentially dangerous tasks) into a digitalized and connected environment in which robots, machines, and devices can be able to run the operations independently. So, the smart factories with this process automation not only minimize human error and the risk of accidents but also offer more opportunities to take on more complex roles.

For example German aircraft engine manufacturer MTU Aero Engines is engaged in testing its applications on blade integrated disks (blisk) with 5G-based production technology to make efficient operations. The blisks are high-tech components that are used for jet engines, which require the utmost accuracy to produce. So, if we talk about the total lead time it takes to create a blisk is nearby 3-4 months. But with the involvement of new 5G-enabled production technology (involved sensors and IoT technology), the company was successfully able to create an automated factory over one network, and time got reduced to 75% (instead of 3-4 months)

Thus, 5G is playing a major role among these smart factories - it provides manufacturers the ability to create highly reliable systems, which can support the web of information passing through a variety of machines as well as devices.

Remote monitoring of production assets

5G use cases in manufacturing technology also enable remote monitoring of production assets. Smart factories (Industry 4.0 supports making the smart factories) can monitor production assets via remote controls. This technology facilitates operators so that operators can easily locate and manage assets, obtain actionable insights in real-time, and configure the machinery to optimize quality, safety, and efficiency (live monitoring is the major benefit on the factory floor, it can also accelerate certain SOPs outside of it). For example, one company, “Siemens in Mexico has executed its first live remote monitoring system for FAT (Factory Acceptance Tests), which proves that all the equipment manufactured by Siemens is conformed to the customer’s contract specifications. So, at this stage, customers generally should be present at the factory in person to conduct the FAT, but due to the live monitoring remote technology (it’s possible because of 5G), customers can supervise the FAT even from their remote locations” – according to the source Enterpriseiotinsights.com.

Furthermore, 5G coverage is beneficial for live streaming and remote monitoring, and in the future, it will be more seamless, accurate, and secure, thereby allowing operators to broaden their application and troubleshoot problems if anything occurs.

Collaborative robotics

Manufacturers are employing a variety of robots (they can move products from one location to another) these days for industrial tasks, and study reveals that manufacturing robots will see significant growth in the next few years. Industrial robots are designed in such a way to work in the warehouse along with humans, and the robots get connected using a wired system because the data required to power a warehouse of robots cannot be supported by current wireless speeds. Here comes 5G that will make robot use in manufacturing faster and more efficient without the limitation of cables.

For example, a U.K. based online grocery market company- Ocado (their smart factory in Andover, England has over 1,100 robots) makes use of collaborative robotics are actively engaged in picking up items from crates and delivering them to packing stations, thereby successfully fulfilling thousands of groceries orders every week.

Augmented reality

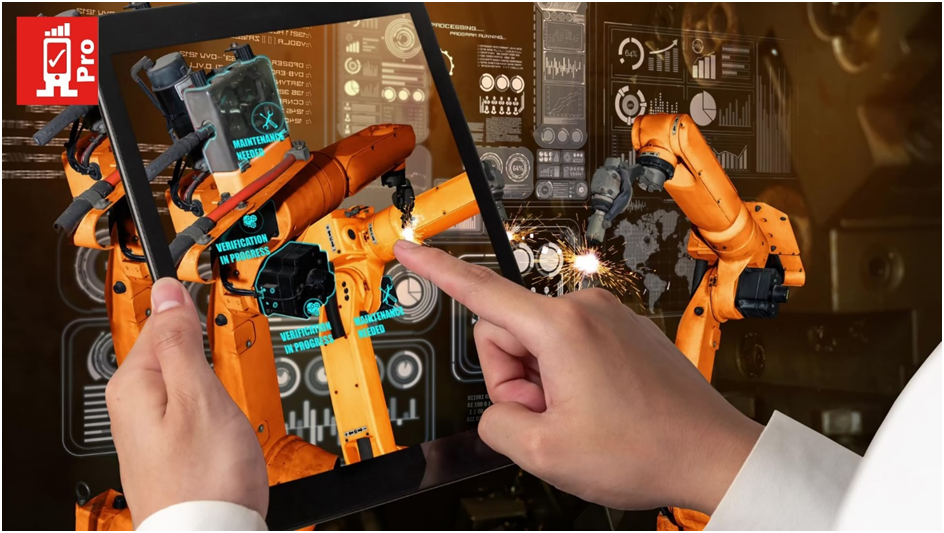

5G technology not only provides low latency and stable connectivity but also enables Augmented Reality (AR) troubleshooting for repairing electronic boards. For example, Ericsson has been experimenting with augmented reality (AR) overlays in their factory, which is beneficial for technicians as they can repair electronic boards (with the help of AR) without referring to blueprints or word documents.

According to the source Enterpriseiotinsights.com, when technicians troubleshoot a faulty unit, they spend 50% of the total time searching for information from documents, manuals, and schematics. But with AR troubleshooting, technicians can identify faulty parts of an electronic board quickly and the average fault detection time gets reduced by 15%. Moreover, AR for repairs also lessens the component replacements, leading to energy consumption savings, as well as reduced chemical use, waste, and scrap.

Additive manufacturing

Additive manufacturing or 3D printing is creatinga major impact on the manufacturing industry as 3D printing transforms spare parts management. As additive manufacturing plays an eminent role in the manufacturing industry, several warehouses these days maintain a huge inventory of spare parts, especially for those customers who are still operating older machines. For this reason, warehouses can be able to forecast the exact demand for spare parts so that they canuse a 3D printer to create the part as per requirements and successfully ship the order based on one-time requests for spare parts.

For example, American multinational home appliance manufacturer Whirlpool (an American home appliance manufacturer)has adopted 3D printing through a partnership with the Singapore service bureau Spare Parts 3D - using this technology to reduce obsolescence and fulfill part-shortage areas. And this in result cost savings for the company and enables customers to receive brand new spare parts whenever they need those. So here the development of 5G can boostthe additive manufacturing process by facilitating operators to connect with multiple standalone 3D printers, which can be beneficial (for operators) to monitor the 3D printing processes remotely - according to Singapore operator, Singtel.

The importance of the 5G testing tool for industry 4.0

When the rollout of 5G communication networks promises to be an advantage for telecommunication and manufacturing companies globally, telecom system integrators and RF engineers require efficient 5G development tools to deliver the customers Quality of Experience(QoE) and Quality of Service(QoS), which means end-user experience. So here comes RantCell–a network testing and monitoring solution (ping test, speed test, Call Test, etc). Some of the KPIs that RantCellcapture for tracking are Downloading speed, Uploading speed, Latency, coverage(RSRP, RSCP, RSSI), Quality(EcNo, RSRQ, SINR), etc.

Benefits of using RantCell:

-

Inexpensive to use as you can use the RantCellto measure indoor and outdoor private networks for 4G/5G.

-

Performing 5G(and 4G, 3G, and 2G too) testing with RantCell is convenient and time-savingwith various test automation features like schedule Tests and a state-of-the-art Dashboard.

-

RF engineers will require lower investment in terms of the field test.

-

RantCell can be used for almost alluse cases such as 5G tester app,5G Wi-Fi tester,5G network tester,5G internet tester, and 5G RF tester

-

Continuous monitoring of performance of private networks from end user perspective.

Conclusion

As the automation of manufacturing is increasing faster, the development of 5G technology is intended to have a dramatic impact when it comes to the growth or evolution of the sector. And this new generation of wireless technology 5G has the potential to play a most important part in the Fourth Industrial Revolution – Industry 4.0.According to Ericsson’s Mobility Report, there will be 1.5 billion 5G subscribers globally by 2026.

5G in manufacturing offers huge opportunities by allowing for both improved connectivity and exciting applications in robotics and artificial intelligence. According to the experts’ prediction, we will see the creation of more responsive and efficient robots to take on different tasks within factories (help in leading to the increased automation of manufacturing) and in the industry, 5G could result in a massive productivity and performance boost.